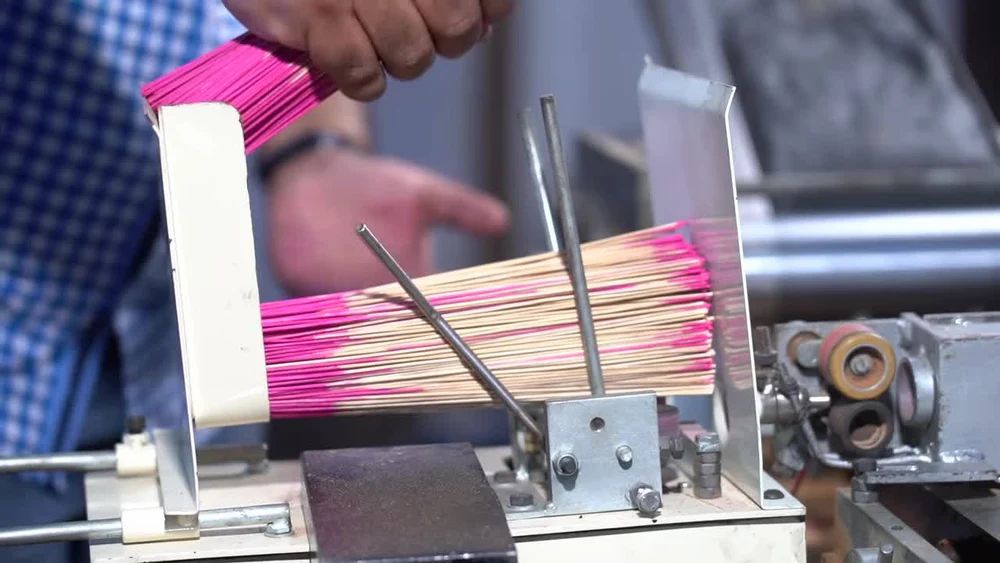

Automatic Dhoop Agarbatti Making Machines – Capacity: 50 Kgs Per Shift

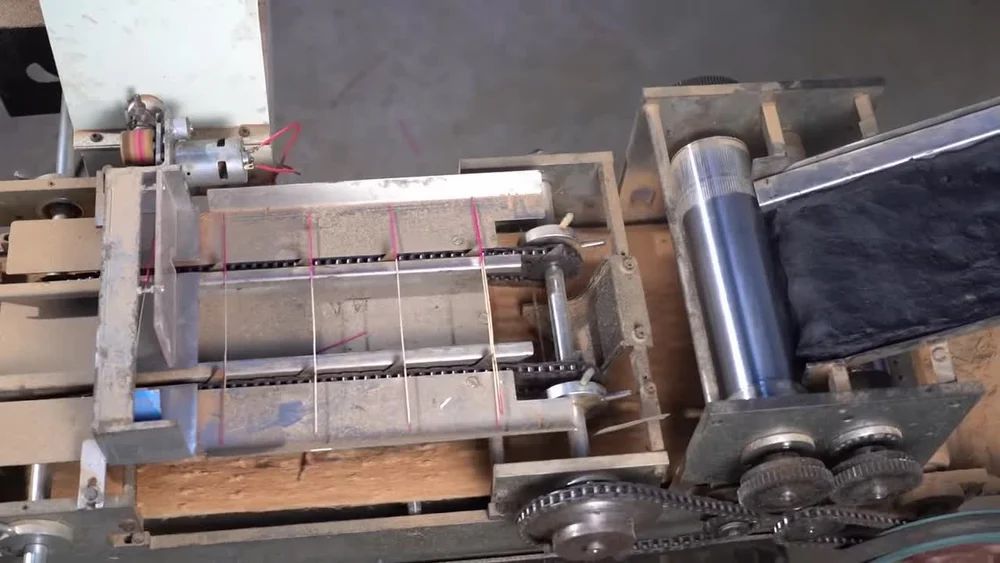

Transform your incense manufacturing with our state-of-the-art Automatic Dhoop Agarbatti Making Machines, designed to handle up to 50 kgs per shift. Priced competitively at ₹1,25,000, our machines offer an exceptional blend of efficiency and affordability, meeting the needs of both small and large-scale manufacturers.

Why Choose Our Dhoop Agarbatti Making Machines?

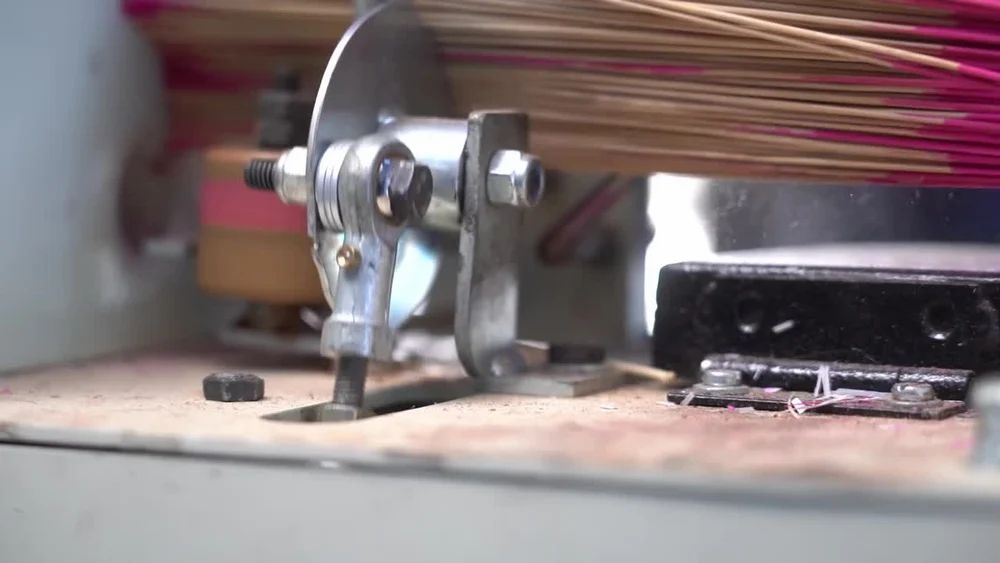

Our machines are engineered to enhance production efficiency while maintaining high quality. Unlike traditional methods, which can compromise the integrity of the agarbatti due to high pressure extrusion, our machines preserve the essential qualities of the raw materials. This results in agarbatties with better aroma diffusion and extended shelf life.

Quality Assured: Hand Rolling vs. Machine Production

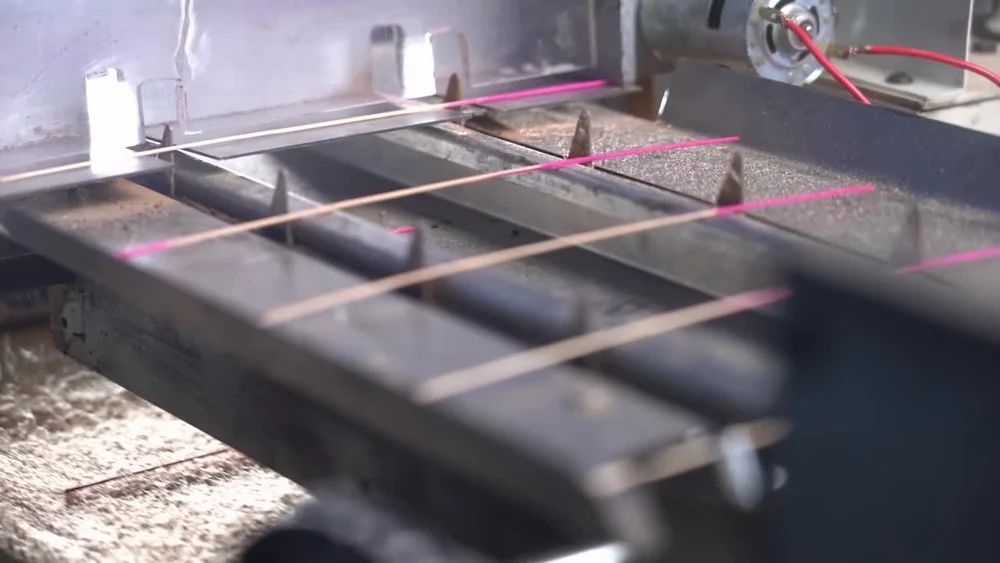

When it comes to quality, hand-rolled agarbatties stand out. The traditional hand-rolling method retains the premium characteristics of costly raw materials. In contrast, machines that use high pressure extrusion, such as those found in Vietnamese production methods, often produce agarbatties with poor porosity and reduced quality. Our automatic machines emulate the hand-rolling process, ensuring superior quality in every batch.

Bamboo Sticks: Traditional vs. Imported

Our machines are designed to use square bamboo sticks, which are traditional in Indian incense production. These sticks support better fragrance diffusion compared to imported round bamboo sticks, which are often treated with chemicals and polished with substances like dolomite and wax. Imported bamboo is genetically modified for commercial purposes, negatively affecting fragrance diffusion. Additionally, square bamboo sticks are more cost-effective, averaging 30% of the price of imported round sticks.

Domestic and Export Opportunities

In the domestic market, the demand for dipping agarbatties is growing due to the influx of imported raw materials. However, MASALA and FLORA agarbatties remain highly desirable in India due to their unique characteristics and production challenges, making them a lucrative market segment. For exports, only high-quality agarbatties are preferred, and hand-rolled options are often favored. Our machine offers a practical solution for producing high-quality agarbatties efficiently.

Advantages of Automation

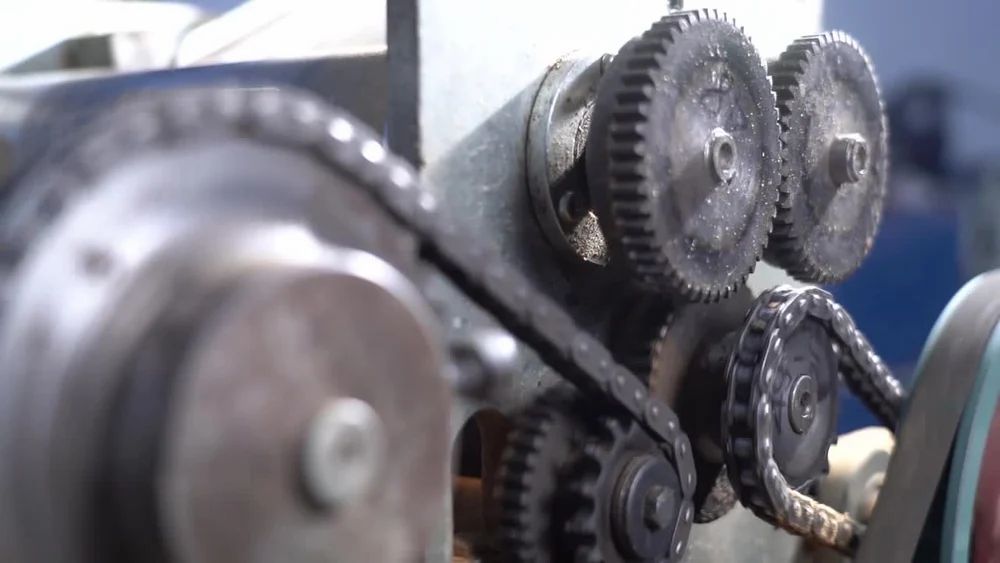

Automation addresses the challenges of skilled labor shortages and high manual production costs. Many recognized brands still rely on conversion manufacturers for MASALA and FLORA agarbatties due to the lack of skilled labor. Our machines reduce dependency on these conversion manufacturers, allowing you to retain more profit and speed up the development of new product variants. This automation also reduces delays and increases overall production efficiency.

Preserve Quality with Advanced Technology

Our MASALA and FLORA Agarbatti Making Machine combines advanced technology with traditional methods to maintain the quality of hand-rolled agarbatties while overcoming the challenges of manual production. With a growing shortage of skilled labor and rising production costs, our machine represents a significant advancement in the agarbatti industry, offering a reliable and cost-effective solution for modern incense manufacturing.

Company Information

Located in Tamil Nadu, our firm operates under the legal status of an Individual – Proprietor. We have been manufacturing incense products since our establishment in 2019, with an annual turnover ranging between Rs. 1 – 2 Crore. Our online business commenced in August 2015, and we are registered with GST number 33FULPS6133Q1ZS. With a dedicated team of 11 to 25 employees, we are committed to delivering quality and innovation in the incense industry.

About company :

💼 Company : Incense Industries

👨🏻💼 Contact name : Deepak Kumar

📞 Phone number : +91-8043875614

📭 Full adress : Building No. 126/141, Gandi Adigal Salai, Kumbakonam – 612001, Thanjavur, Tamil Nadu, India

🌏 Localisation : View map

✈ Export countries : N/A

🔐 Export code : N/A

Details

| Area | Tamil Nadu |

|---|---|

| Material | |

| Incense Stick length | |

| Item Weight | |

| Power Required | |

| Type of Stick | |

| Motor Type | |

| Automation Grade | |

| Warranty | |

| Machine Speed | |

| Dimension | |

| Production Capacity | |

| Count of cones per minute | |

| Minimum Order Quantity |